Culture media are indispensable in modern food safety programs, serving as the backbone for detecting harmful pathogens like Salmonella, Listeria monocytogenes, and Escherichia coli. With rising global food safety regulations, laboratories must adopt precise methods to prepare and apply dehydrated (dry powder) culture media effectively. Proper usage not only ensures compliance with stringent standards like ISO 11133 but also minimizes false results and production recalls. This comprehensive guide explores streamlined workflows for food quality control, from media selection to troubleshooting common challenges.

Selecting the Right Culture Media

1. Media Types for Specific Pathogens

- Selective Media: Suppress competing microorganisms while promoting target pathogen growth.

- Example: Xylose Lysine Deoxycholate (XLD) Agar for isolating Salmonella in meat products.

- Differential Media: Visually distinguish pathogens via biochemical reactions (e.g., color changes).

- Example: MacConkey Agar identifies lactose-fermenting coliforms in dairy.

- Enrichment Broths: Amplify low-concentration pathogens in complex matrices (e.g., Buffered Peptone Water for Salmonella pre-enrichment).

2. Regulatory Compliance

Validate media against region-specific standards:

- Global: ISO 11133:2014 for quality assurance in media preparation.

3. Storage & Stability

- Store unopened dry powder media in airtight containers at 15–25°C, away from humidity.

- Post-rehydration, use liquid media within 48 hours or sterilize immediately.

Step-by-Step Media Preparation

1. Precision Weighing

- Use calibrated analytical scales to measure powder (±0.01g accuracy).

- Example: 50g powder per 1L distilled water for standard nutrient agar.

2. Rehydration & Sterilization

- Heat the mixture to 100°C while stirring to achieve a homogeneous solution.

- Autoclave at 121°C for 15 minutes to eliminate spores and contaminants.

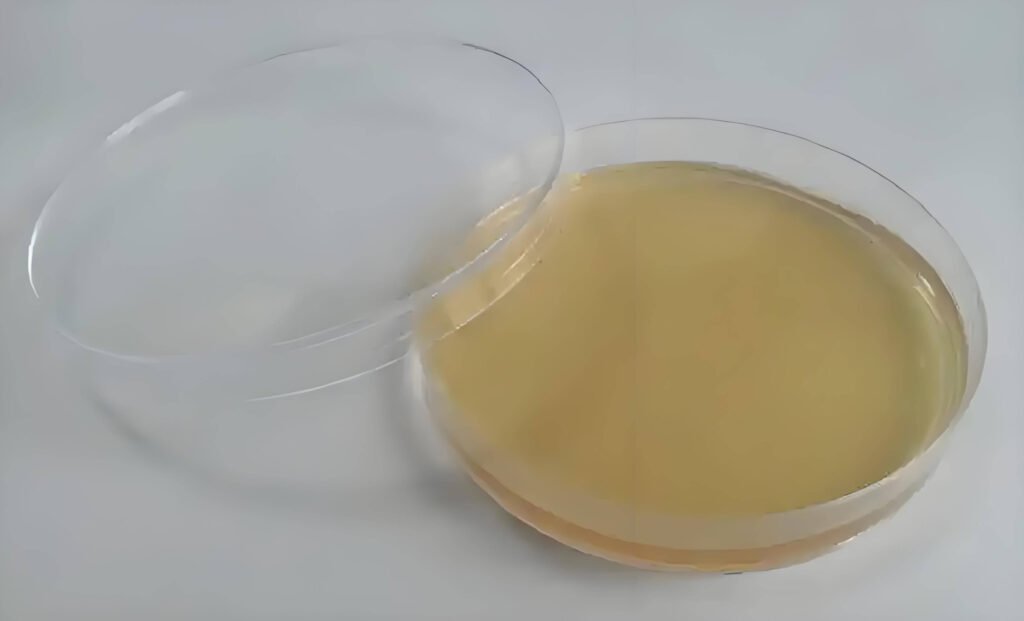

3. Plate Preparation

- Cool media to 45–50°C (test with infrared thermometer).

- Pour 15–20mL per Petri dish under laminar airflow to prevent airborne contamination.

4. Quality Checks

- Perform growth promotion testing using reference strains (e.g., E. coli ATCC 25922).

- Discard batches if contamination or inconsistent pH (target 6.8–7.2) is observed.

Key Applications in Food Safety

1. Raw Material Testing

- Screen grains, spices, and additives for Aspergillus (using Dichloran Rose Bengal Chloramphenicol Agar).

2. Environmental Monitoring

- Swab processing equipment with Contact Plates to detect biofilms or Staphylococcus aureus.

3. Finished Product Analysis

- Incubate samples at 37°C for 24–48 hours to assess aerobic colony counts in packaged foods.

4. Challenge Testing

- Validate shelf life by inoculating products with target pathogens and monitoring growth inhibition.

Troubleshooting Common Issues

1. Contaminated Media

- Cause: Improper sterilization or airborne particles during pouring.

- Solution: Re-autoclave or discard plates; sanitize workbenches with 70% ethanol.

2. Weak or No Growth

- Cause: Incorrect incubation temperature or expired media.

- Solution: Calibrate incubators quarterly; check batch expiration dates.

3. Crystallization in Powder

- Cause: Exposure to moisture during storage.

- Solution: Store media with silica gel desiccants; discard clumped batches.

Industry Standards & Best Practices

- ISO 11133:2014: Mandates lot-specific performance testing for media.

- USP <61>: Specifies microbial limits for non-sterile pharmaceuticals, applicable to food additives.

- HACCP Integration: Use media to validate critical control points (e.g., pasteurization efficacy).

FAQs

Q: How long can prepared agar plates be stored?

A: Up to 4 weeks at 2–8°C in sealed bags to prevent dehydration.

Q: Can media detect antibiotic-resistant strains?

A: Yes—supplement with selective agents like cefixime for ESBL-producing E. coli.

Q: Why does pH matter in media preparation?

A: Most pathogens thrive at neutral pH (6.5–7.5). Deviations inhibit growth or promote contaminants.

Conclusion

Mastering culture media protocols is essential for safeguarding food supply chains against microbial threats. By aligning with global standards like ISO 11133 and leveraging precise preparation techniques, laboratories enhance accuracy, compliance, and operational efficiency. Dehydrated media offer unmatched consistency and shelf life, making them ideal for high-throughput food testing.

Recent Posts

- How Culture Media Impact the Precision of Cosmetic Microbial Testing

- Optimize Lab Efficiency with Granular Culture Media

- Maximizing Microbial Culture Success with High-Quality Media

- Advantages of Ready-to-Use Petri Dishes in Microbial Testing

- Top Benefits of Using Ready-to-Use Petri Dishes in Microbial Testing